Rilson Flange Pipe Gasket Ni Spiral Wound Gasket

Basic Info.

| Model NO. | RS1 |

| Stamping | as Per to Customer`S Request |

| Certificate | ISO9001:2015; ISO9001:2008; SGS; TUV |

| Supplier | 15 Years of Manufacturing Experience |

| OEM&ODM | Yes |

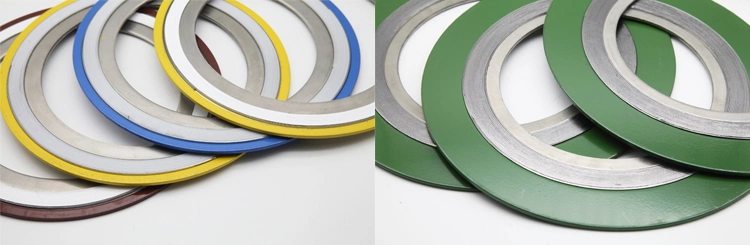

| Color | Epoxy, Zinc Plated |

| Thickness | 0.4mm-6.0mm |

| Size | 1/2" to 60" |

| Transport Package | Wooden Case |

| Specification | ASME, BS, JIS and EN(DIN) standards and others |

| Trademark | Rilson |

| Origin | China |

| HS Code | 84841000 |

| Production Capacity | 1, 000, 000PCS/Month |

Product Description

Sprial Wound GasketSpiral wound gaskets(SWG) have become extremely popular due to the wide variety of available styles and sizes. Spiral wound gaskets can be fabricated of any metal which is available in thin strip and which can be welded; therefore, they can be used against virtually any corrosive medium dependent upon the choice of the metal and filler. They can be used over the complete temperature range from cryogenic to approximately 2000ºF (1093ºC). This type of gasket can be used in all pressures from vacuum to the standard 2500 pressure class flange ratings. Spiral wound gaskets can also be manufactured with variable densities, i.e.relatively low density gaskets for vacuum service up to extremely high density gaskets having a seating stress of approximately 30,000 psi (207 MPa).The softer gaskets would require a seating stress in the range of 5,000 psi (34 MPa).

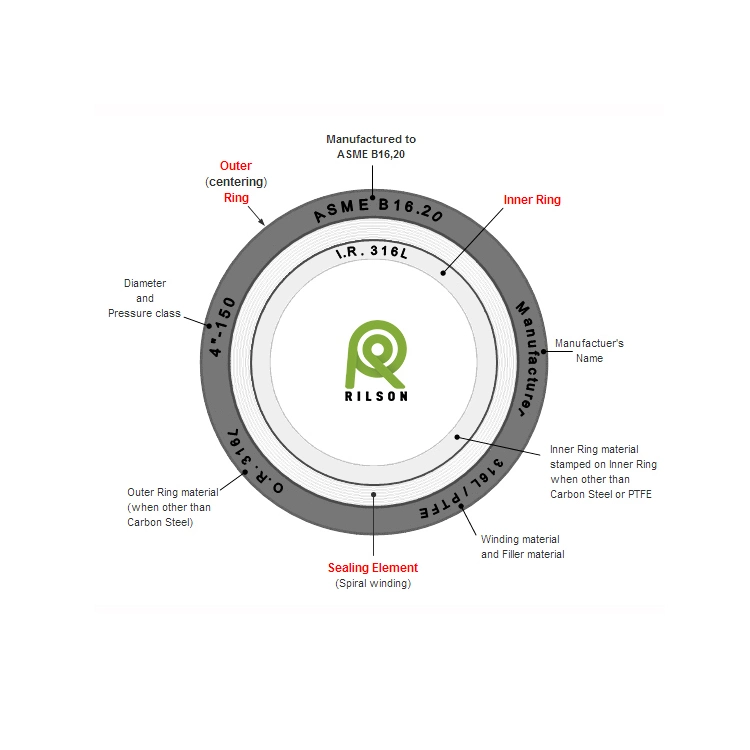

Spiral Wound Gaskets with Inner Ring

Spiral Wound Gaskets with inner Ring is consisted of a spiral wound sealing component with a solid metal inner ring. Inward buckling of spiral-wound gaskets has been identified as a potential problem. Inner rings shall be furnished with all spiral-wound gaskets having PTFE filler material. Inner rings for flexible graphite-filled, spiral-wound gaskets shall be furnished unless the purchaser specifies otherwise. For all filler materials, inner rings shall be furnished in spiral-wound gaskets for

(a) NPS 24 and larger in Class 900(b) NPS 12 and larger in Class 1500(c) NPS 4 and larger in Class 2500 Inner rings are required for these gaskets due to high available bolt loads, which may result in outer ring damage. Suitable for male and female pipe flanges.

Strength of Spiral Wound Gasket> Spiral Wound Gasket is the ideal gasket in the semi-metallic category. A narrow strip of V-shape metal hoop is spirally wound under tension with a filler cushion between the lamination of the metal and is spot-welded at both ends.> This unique construction of a spring-like metal and soft filler provides gasket excel-lent characteristics.> Resistance to high temperature and high pressures.> Excellent sealability is maintained with comparatively small gasket area.> Great resilience which allows the gasket to adjust automatically to change in operating conditions, such as pressure and thermal shocks, vibrations etc.

Product Descriptio

| Product Name | Industrial seal metallic spiral wound gasket carbon steel gasket |

| Size | 10-3000mm |

| Hoop material | 304,316,316L,Mon400,Inconel,Etc. |

| spiral Wound gasket coefficient | m=2.5-4 |

| Use pressure | ≤25MPa |

| Use temperature of spiral wound gasket | -196 C -700 C (not more than 600 C in oxidizing medium) |

| Minimum pretension ratio | Y=68MPa |

| Flanges standard | ASME B16.20 |

| Type,Flange | 1.Basic type: Tongue and Groove 2.With outer ring: Raised face and Flat face 3.With inner ring: Male and Female 4.With inner and outer ring: Raised face and Flat face |

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,we can pack the goods in your branded boxes after getting your authorization letters.Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packagesbefore you pay the balance.Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.Q4. How about your delivery time?

A: Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time dependson the items and the quantity of your order.Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost andthe courier cost.Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before deliveryQ8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;2. We respect every customer as our friend and we sincerely do business and make friends with them,no matter where they come from.